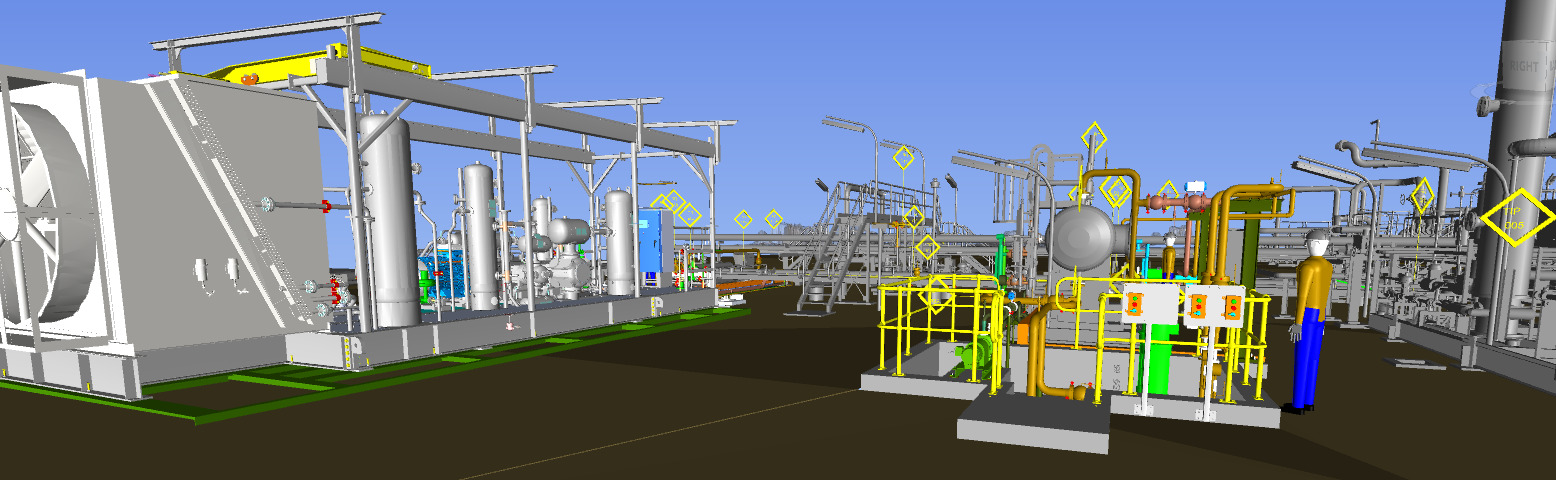

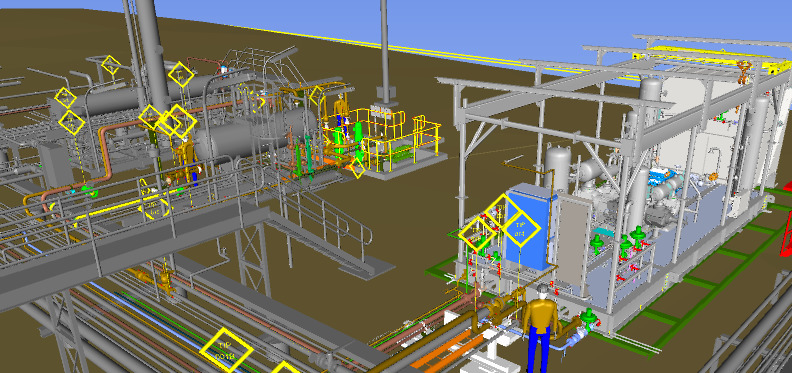

Sedgman Prudentia developed the technical solution to recover flared gas from two point sources of different operating pressures to reduce emissions, increase saleable product yield and an LPG specification liquids stream at a remote gas processing facility.

Solution

Sedgman Prudentia developed the concept design, FEED design including compressor and flare package specification, CAPEX cost estimate and detailed design to recover saleable gas to reduce flare emissions. Sedgman Prudentia completed the process modelling (HYSYS) and developed the engineering technical solution to implement within the existing facility. The initial concept was to reconfigure an existing compressor package but this proved too costly due to the level of rework for the compression duty which was two separate two stage reciprocating compression duties on the one compressor frame. The final design included a two (2)-stage flare gas compression package, new horizontal flare tip with atomising nozzles, oily water and recovered oil pump replacements, flare pit modifications to extend life and improve drainage, plus balance of plant Structural/Mechanical/Piping (SMP), new switchboard and associated Electrical / Control/ Instrumentation. The design catered for staged development to allow for implementation within a planned shutdown window.